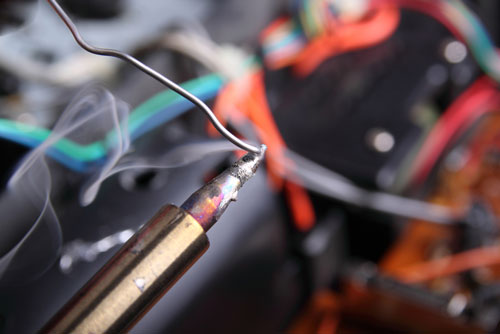

Soldering has had a profound effect on the electronics industry.

At Express Assemblies Ltd we demonstrate high quality soldering and de-soldering techniques to ensure all products are manufactured with precision and accuracy.

At Express Assemblies Ltd, we understand that ‘soldering’ is a critical skill when manufacturing and assembling any electronic product and over the years have mastered a great deal of expertise to ensure a long reliability of soldered joints that can work in harsh environments.

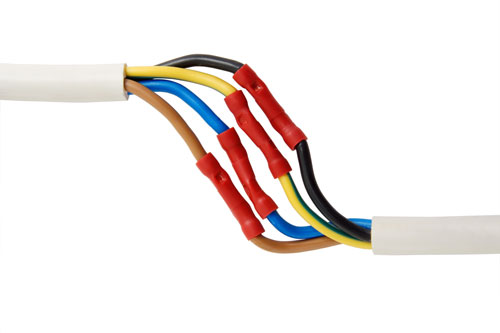

We use both tin lead solder and lead free solder in our products, all of which meet regulatory control standards and offer quality termination solutions.

We have established clear standards and acceptance criteria when producing soldered connections and ensure that the end result exhibits the necessary electrical and mechanical properties to ensure high quality performance.

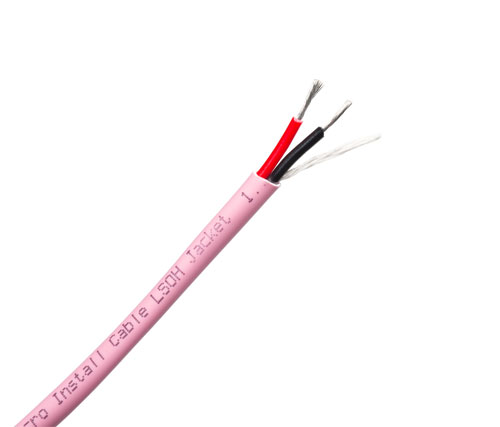

In regards to our tinning operations, we operate in a similar stance to our soldering practices. We have a number of solder or tinning baths which are used to coat our cut and prepared wires with molten solder to then increase its solder ability.

Our tinning procedure is used on wires that require further soldering to components like PCBs or other solder able surfaces but ultimately the tinning process is another form of wire termination, so similarly to crimping the wires will not splay or become damaged.

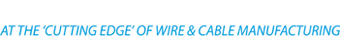

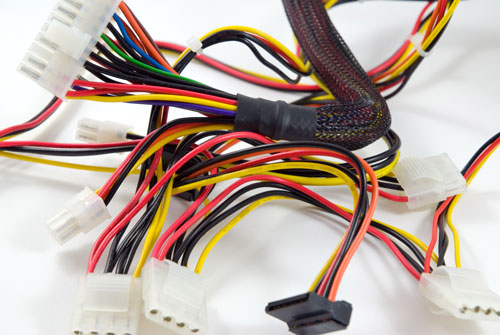

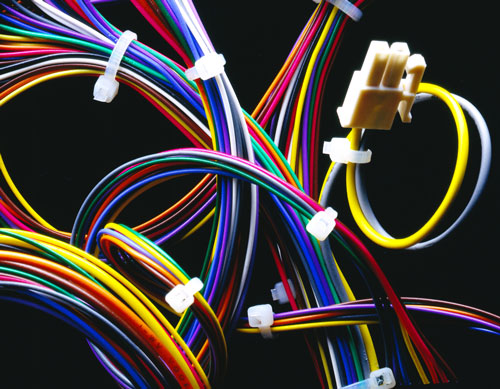

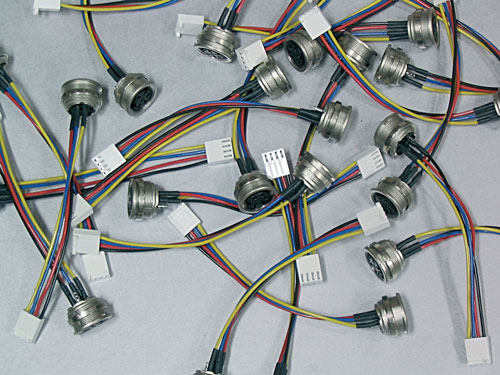

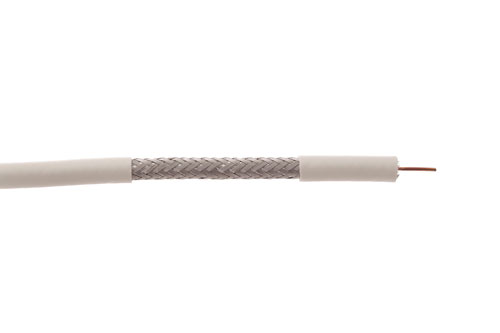

Our Products

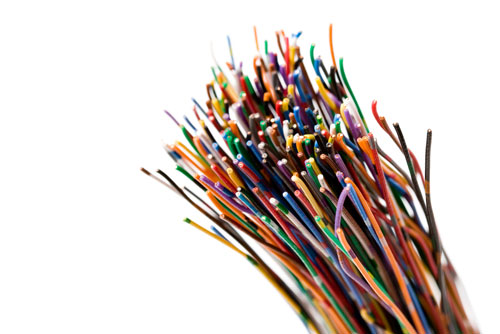

Providing a global solution for all your wire & cable assembly needs

Contact us today by calling 0116 260 3589, emailing us at [email protected] or use our online

Contact Form