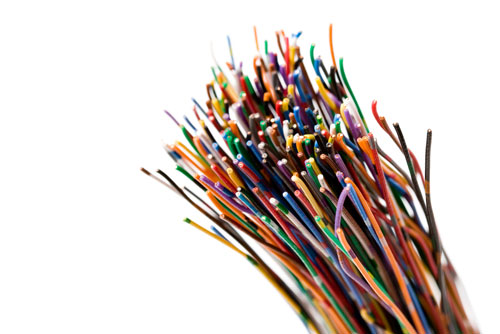

Another termination process we can offer is wire or cable ferruling.

We have a range of ferruling capabilities available and have the latest industry ferruling tools and equipment, on site.

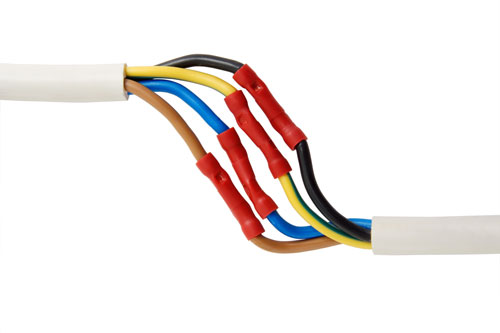

A similar process to crimping, ferruling is used to terminate stranded wires and prevent conductors from corrosion. A ferrule acts as a consistent, reliable and robust connection ensuring product quality is not compromised in any way.

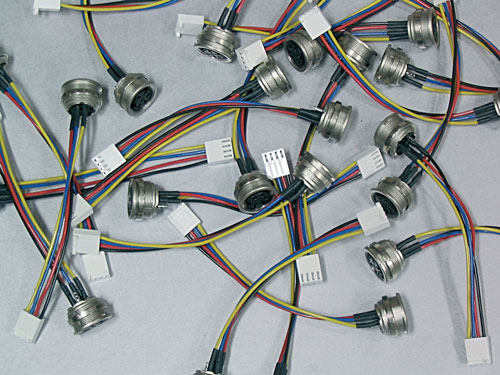

At Express Assemblies Ltd we specialise in the use of bootlace and pre-insulated coloured ferrules, stocking sizes ranging from 0.25mm to 95mm. We have a number of automated bootlace ferrule machines which help to streamline our manufacturing process when working with bulk volume quantities, and improve overall efficiency as well as offer cost-effective solutions to our customers’ enquiries.

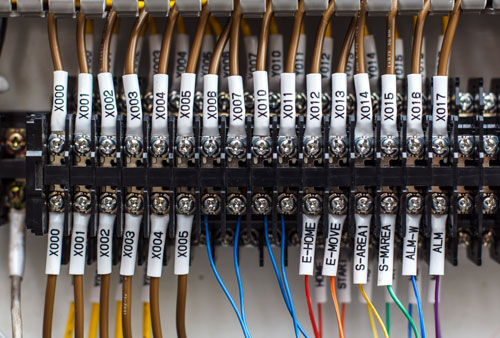

We can also offer the use of twin end ferrule terminals, used for when two wires need to be crimped together to make a connection. We work with both French and German colour code standards which mean we can cater to deal with any bootlace ferrule enquiry.

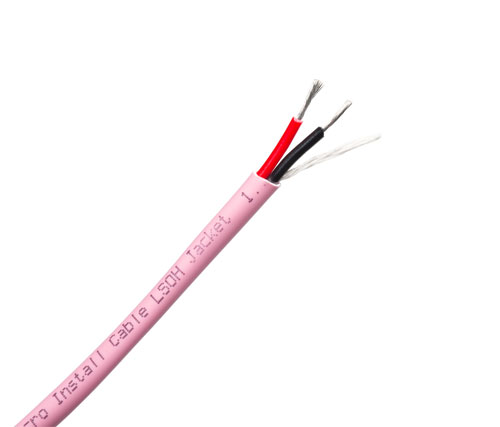

We can also work with uninsulated cord end ferrules which can be used for single or double wire configurations. All our uninsulated ferrules meet DIN requirements for wire containment and offer a reliable, sturdy connection for wire product with limited space applications.

Finally, we offer ranging pin/barrel lengths to meet customer requirements. For instance, standard bootlace pin lengths are 8mm, however we stock ferrules which have an increased barrel length ranging from 10-18mm depending on the size of the ferrule. These increased pin or barrel lengths are used to suit specialised or ergonomically designed product applications.

Our Products

Providing a global solution for all your wire & cable assembly needs

Contact us today by calling 0116 260 3589, emailing us at [email protected] or use our online

Contact Form